技术交流

蒸汽灭菌器不锈钢表面资讯(第一期)[2023-08-21 ]

前言

在加工医疗产品时,高质量绝对是至关重要的。德国无菌供应学会(DGSV e.V.)的目标是提高医疗产品加工的整体质量。实现这一质量改进的方法之一是提高工艺可靠性,这是我们的主要目标。患者是我们所做一切的重点。此外,实际的行业经验也可以帮助提高质量。红锈是蒸汽灭菌过程中一个众所周知的质量问题。但是实际上是什么导致了红锈的出现,操作人员如何消除这些原因并防止它们成为一个问题呢?在这本手册中,你会发现对这个非常高质量的问题的描述,以及你可以采取的步骤来成功地解决这个问题本身和找到它的起因。

Maik Roitsch

DGSV主席

Foreword

When processing medical products, a high level of quality is absolutely critical. The mis- sion of the German Society of Sterile Sup- ply (DGSV e.V.) is to improve the overall quality of medical products processing. One of the ways to achieve this quality im- provement is by increasing process reliabi- lity, which is our primary objective. The patient is the focus of everything we do. In addition to this, actual industry experience can also help to improve quality. Rouging is a well known quality issue in the steam sterilization process. But what actually cau ses rouging, and how can operators elimi- nate these causes and prevent them from becoming a problem? In this brochure, you'll find a description of this very quality issue, as well as steps that you can take to successfully address both the issue itself and its causes.

Maik Roitsch

DGSV Chairman

介 绍

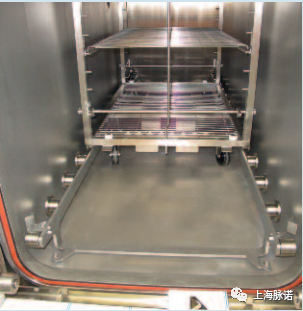

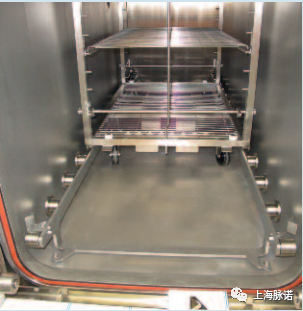

图1:状况良好的腔室的典型图像

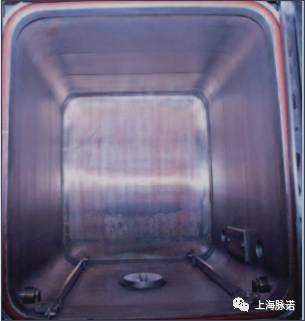

图2:重复使用后的腔室状况(可见腔室变色)

当医疗器械被再加工时,它们会在蒸汽消毒器中进行消毒,这是专门为手头的任务而特别优化的。作为一种公认的观念,蒸汽灭菌是一种研究充分、可靠的处理方法。在腔室的技术设计中,使用高合金奥氏体不锈钢合金,如1.4301、1.4404、1.4571和其他类似合金作为结构材料。图1和图2显示了一个典型的蒸汽消毒器的例子,可以看到快速灭菌柜的内部。 在许多应用情况下,实际操作经验显示,在灭菌室的使用寿命中,灭菌室内部的不锈钢抛光表面经常出现不希望的变色。这些所谓的抗锈不锈钢表面的变化(见图2)的变化往往使负责MPPU/CSSD(医疗产品处理单元/中央无菌服务部门)仪器运行的员工感到不安。 本指南的目的是在某些情况下深入解释上面所描述的变化背后极其复杂的相关原因,并展示各种不同的影响因素。然而,我们应该首先注意到,这些类型的表面改变通常是几个不同因素造成的结果,这些因素甚至可以根据个别场景相互作用和/或相互恶化。 在分析与不锈钢表面不常见的沉积物有关的变色问题背后的原因时(这在单个的韧性方面差别很大),通常的反应是首先联系以下一个或多个组织:建造服务商、WD制造商和所使用的工艺化学品的供应商。 上述每个接触点从其自身的主观角度选择性地处理不锈钢表面上的变色/(不希望的)膜的问题,然后可以回答其系统或产品正在完美地运行,并且不承担造成变色的责任。从操作人员的角度来看,这种处理方法通常对需要进行的问题分析没有帮助,也不有利于有效地解决问题。 在分析根本原因时,需要首先检查供应给设备的水的质量,以及从灭菌蒸汽中产生的凝析水的组成。 此外,建议一个专家对从受影响的不锈钢表面的变色中提取的拭子/磨损样品进行化学物理分析。对这一分析结果的解释将得出关于薄层的来源和原因的初步结论。 然而,所有必要的介质供应参数即使符合,永久的薄膜/变色也完全有可能出现在灭菌器室的内表面。 这本手册提供了关于表面变色的潜在原因的基本和补充的提示和信息,以及处理这些典型的麻烦现象的建议。 文本随附的插图和数据有助于确保涵盖问题的整个范围,包括所有相关因素。已经特别标注解释蒸汽灭菌的主题,以及在这种背景下如何发生变色的潜在原因。 在这个连接处,应当注意的是,这种被称为均匀腐蚀的形式,这些不锈钢表面的薄膜/变色也可以由除了本手册中描述的造成红锈以外许多其他极其多样化的影响因素引起。例如,无腐蚀性不锈钢合金表面的变色和与腐蚀相关的变化可能有以下已知的原因:

➡水或蒸汽的质量不够好

➡腔室表面没有按照正确制造、和/或按照相同标准的材料

➡合金质量不好

➡制造腔室使用了不适合的制造技术

➡灭菌材料中使用了不合适的物质

➡被引入或带入化学物质进入了腔室

➡不锈钢表面工作的不当方法的应用

➡对腔室和装载推车的化学攻击,例如:不适合清洁的化学物质

➡化学指示物或贴纸

➡造成腐蚀风险的二级工艺(例如:磨擦腐蚀、点蚀、接触腐蚀等)

在每一种特定的情况下,其他因素也可能作为一个潜在的原因加以考虑。

Introduction

When medical instruments are reprocessed, they are sterilized in steam sterilizers that have been specially optimised for the task at hand. As a concept that has been known about for years, steam sterilization is a well researched and reliable processing method. For the technical design of the chambers, high-alloyed austenitic stainless steel alloys, such as 1.4301, 1.4404, 1.4571, and other similar alloys, are used as structural materials. Figures 1 and 2 show examples of a typical steam sterilizer, with a view of the sterilization chamber interior. In many application cases, actual operating experience has shown that, over the course of the sterilization chamber's service life, undesired discolouration often appears on the initially bright finish of the stainless steel surfaces in the chamber's interior regions. These types of changes in supposedly rustresistant stainless steel surfaces (see Figure 2) are often disconcerting to the employees in charge of the MPPU/CSSD (medical products processing unit / central sterile services department) and to those responsible for instrument processing. The goal of this guide is to provide an in- depth explanation of the, in some cases, extremely complex interrelated causes behind the changes described above, and to also present various different influencing factors. However, we should start by noting that these type of surface alterations are typically the result of several different factors that can even interact with and/or exacerbate one another depending on the individual scenario. The usual response when analysing the causes behind the discolouration problems (which vary greatly in terms of individual tenacity) found in connection with the typically unfamiliar deposits on stainless steel surfaces is to first contact one or more of the following groups: building services, the manufacturer of the WD and the suppliers of the process chemicals used. Each of the aforementioned points of contact approaches the issue of discolouration / (undesired) film on the stainless steel surfaces selectively, from its own individual, subjective perspective, and may then reply that its system or product is working flawlessly, and is therefore not responsible for causing the discolourations. From an operator's point of view, this approach is usually not very helpful for the problem analysis that needs to be performed, nor is it conducive to effectively resolving the problem. When analysing the root cause, it is important to first check the quality of the water being supplied to the devices, as well as the composition of the condensate from the sterilizing steam. In addition, a chemical-physical analysis of swab/abrasion samples taken by a specialist from the discolourations on the affected stainless steel surfaces is recommended. The interpretation of the results from this analysis will allow initial conclusions to be drawn about the sources and causes of the film. However, it is entirely possible that, even if all of the necessary media-supply parameters are complied with, permanent films/ discolourations can appear on the interior surfaces of sterilizer chambers. This brochure provides basic and supplementary tips and information about the potential causes of surface discolourations, as well as recommendations for dealing these typically bothersome phenomena. The illustrations and figures accompanying the text help to ensure that the entire scope of the problem, including all of the related factors, is covered. Particular attention has been given to explaining the topic of steam sterilization and how potential causes of dis- colouration can occur in this context. At this junction it should be noted that, as what is referred to as form of uniform corrosion, these films/discolourations on stainless steel surfaces can also be caused by a host of other extremely diverse influencing factors aside from the rouging effect described in this brochure. Discolourations and corrosion-related alterations in the surface of noncorrosive stainless steel alloys can, for example, have the following known causes:

➡ Inadequate quality of water or steam

➡Chamber surfaces that were not manufactured properly and/or in conformity with standards

➡ Unsatisfactory alloy quality

➡ Application of unsuitable methods for working stainless steel surfaces

➡ Unsuitable manufacturing techniques used in producing the chamber

➡ Unsuitable substances in the sterilization materials

➡ Introduction or carry-over of chemicals into the chamber

➡ Chemical indicators or stickers

➡ Chemical attacks on the chamber or loading trolleys, e.g. through the use of chemicals not suitable for cleaning

➡ Secondary processes posing corrosion risks (e.g. fretting corrosion, pitting,contact corrosion, etc.)

In each specific case, other factors may also come into consideration as a potential cause.

来自:德国的钱伯斯工作组(德语缩写:AKK)的手册

微信公众号

微信公众号