技术交流

1、水及其影响

Water and its effects.

在本文中描述的技术应用中使用未经处理的水(=自来水)是不可取的,因为这种类型的水在大多数情况下不具有必要的纯度水平。因此,自来水必须经过适当的处理,以便作为技术系统中消毒室和/或伴随的蒸汽发生器的给水。

The use of untreated water (= tap water) for the technical application described herein is not advisable, since this type of water does not possess the necessary level of purity in most cases. For this reason, tap water must be treated appropriately in order to be used as feed water for the sterilization chamber and/or the accompanying steam generator in technical systems.

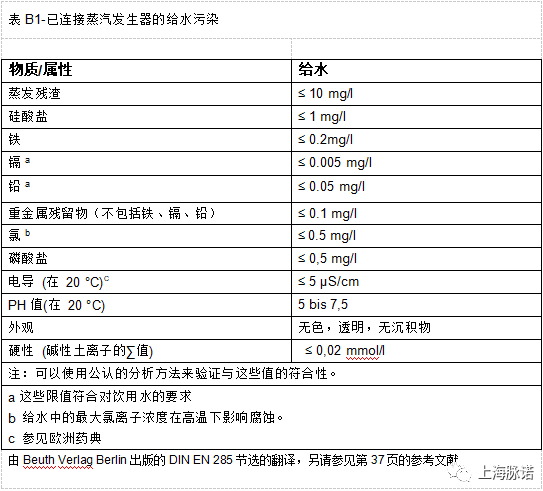

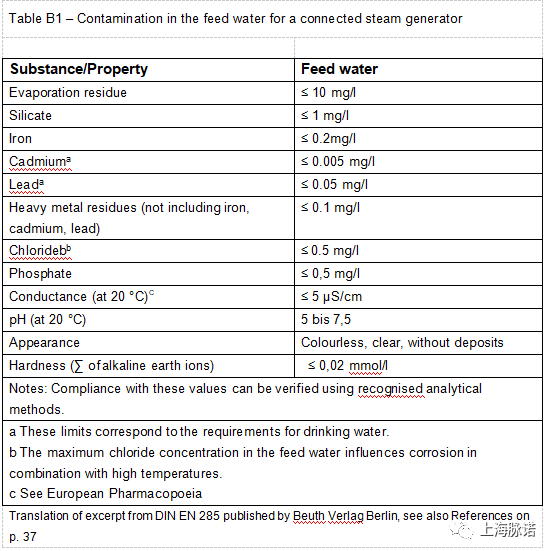

相关标准中规定了必要的水质,其中DIN EN 285标准目前适用于消毒器的水质领域(见表B1)。在实际应用中,自来水通过单一混合床离子交换和/或涉及膜技术(反渗透)的系统进行处理(实际淡化/脱盐化)。在某些情况下,还可以使用额外的电化学脱盐工艺。在每种情况下,目标是以有目标和控制的方式降低自来水中的离子或矿物质含量,水的特定电导率通常被用作水质的重要指标。

The necessary water quality is specified in the relevant standards, with the DIN EN 285 standard being currently applicable to the area of water quality for sterilizers (see Table B1). In practice, tap water is treated (for actual desalination / demineralisation) by means of a single mixed-bed ion exchange and/or in systems involving membrane techniques (reverse osmosis). In some instances, additional electrochemical post-demineralisation processes may also be used. In each case, the goal is to reduce the ion or mineral content of the tap water in a targeted and controlled manner.

1.1水的成分及处理方法

Water constituents and treatment

虽然在用于蒸汽生成的技术性水处理过程中偶尔会遇到引用“去离子水”,但应该注意的是,“去离子水”不是一个定义规范的术语。结合欧洲药典和美国药典,“去离子水”被定义为“纯净水”。因此,每个人都可以自由地解释“去离子水”或“部分去离子水”一词的含义。从技术角度来看,这种情况是非常不令人满意的,特别是当人们认为它似乎是非常重要的精确的定义标准化水质所需的特定应用,也能够采取适当的步骤来监测符合必要的/定义的质量限制。

Though one will occasionally encounter re- ferences to 'deionised water' in practice in the context of technical water treatment for steam generation, it should be noted that 'deionised water' is not a defined normative term. In the binding Ph. Eur. and USP compendiums, 'deionised water' is defined as 'aqua purificata'. As a result, each individual is free to interpret the meaning of the terms 'deionised water' or 'partially deionised water' for his/her own field of activity. From a technical standpoint, this state of affairs is highly unsatisfactory, especially when one considers that it would appear to be extre- mely important to have on hand at all times a precise definition of the standardised water quality required for specific applications, and also to be able to take the appropriate steps to monitor compliance with the required/defined quality limits for the water constituents.

特别是当在水处理中使用混合床离子交换时,对除盐水的特定电导的连续监测和处理水中硅酸含量的测试都很重要,因为后者(或用正确分析的术语表示,硅酸盐含量)不包括在特定电导的典型测量中。

Particularly where the use of mixed-bed ion exchanges in water treatment is concerned, both a continuous monitoring of the specific electrical conductance of the demineralised water and testing for the silicic acid content in treated water are important, since the latter (or in analytically correct terms, the silicate content) is not covered by the typical measurement for specific electrical con- ductance.

先前要求并达到的特定电导值为5µS/cm,并不自动等于允许的硅酸盐含量(小于1mg/l)。硅酸盐或硅酸的量只能用化学方法来确定,而不能通过测量电导率来确定。特别是在使用标准化的混合床离子交换时,人们会遇到反复发生的硅酸/硅酸盐突破离子交换的问题。这就是为什么最终存在于处理过的水中的硅酸/硅酸盐浓度经常被认为是在不锈钢表面形成黄褐色到紫蓝变色的(部分)原因。

A required—and achieved—specific elect- rical conductance value of 5 µS/cm therefore does not automatically equal a permissible silicate content (of less than 1 mg/l). The amount of silicate or silicic acid can only be determined using chemical me- thods, not by measuring electrical conductance. Specifically where standardised mixed-bed ion exchanges are used, one encounters the reoccurring problem of the silicic acid / silicates breaking through the ion exchanges. This is why the silicic acid / silicate concentrations which are ultimately present in the treated water are frequently cited as being the (partial) cause of the formation of yellowish-brown to violet-blue discolourations found on stainless steel surfaces.

其他信息可从德国仪器再处理工作组AKI(“仪器再处理,仪器再处理以保持价值”)在www.a-k-i-.org上出版的红色手册上获得。

Additional information is available from the Red Brochure published by the German Instrument Reprocessing Workgroup AKI ('Instrument Reprocessing, Reprocessing of Instruments to Retain Value') at www.a-k-i- .org.

另一种有些情况下发现于经过不完整或不恰当的处理过程的处理过的水中有不可接受的高浓度的元素,是氯离子。即使在灭菌过程后不锈钢表面干燥时存在ppm量级的少量物质,这也足在表面上的产生一个关键的聚积。在低氯化物浓度下,低耐点蚀等效数量的奥氏体不锈钢合金,如1.401、1.440301、1.4404、1.4571或其他类似合金,表现出对氯化物引导(局部)点蚀和应力腐蚀裂纹的敏感性。

Another element that can in some cases be found in inadmissibly high concentrations in treated water following an incomplete or improper water treatment process (e.g. during water softening) are chloride ions. Even where small amounts on the ppm scale are present as the stainless steel surface dries following thesterilization process, this is enough to cause a critical accumulation on the surfaces. At low chloride concentrations, austenitic stainless steel alloys with low pitting resistance equivalent numbers in particular, such as 1.4301, 1.4404, 1.4571 or other similar alloys, exhibit a susceptibility to what is known as chloride-induced (local) pitting and to stress corrosion cracking.

Figure 3: Chloride-induced pitting

图3:氯化物诱导的点蚀

水处理的另一个重要因素是水中的实际氧含量。在室温下,天然水总是含有一定数量的大气溶解氧。这种氧含量可以通过在水处理过程中大大降低,特别是通过加热。

Another important factor for water treatment is the actual oxygen content in the water. At room temperature, natural water will always contain a certain amount of dissolved atmospheric oxygen. This oxygen content can be greatly reduced by the processes applied during water treatment – in particular, through heating.

然而,由于氧—除了其他条件外—对钝化层的形成至关重要,对在不锈钢表面上保持这些层也相关,氧气的使用方面对于任何其他考虑都是极其重要的。(也请参见第2章) 富含氧化铬的钝化层的破裂,不可避免地导致材料失去其化学惰性的表面性质,并直接导致在关键的环境条件下可能出现腐蚀效应。

However, because oxygen—in addition to other conditions—is critical to the formation of passive layers and also in regard to maintaining these layers on stainless steel surfaces, the aspect of oxygen availability is extremely important for any other considerations. (see also Chapter 2) Disruptions in the passive layer, which is rich in chromium oxide, inevitably cause the material to lose its chemically inert surfac e properties and, as a direct result, lead to the possible appearance of corrosion effects under critical environmental conditions.

来自:德国的钱伯斯工作组(德语缩写:AKK)的手册

微信公众号

微信公众号